Trusted & Respected

Certified Quality

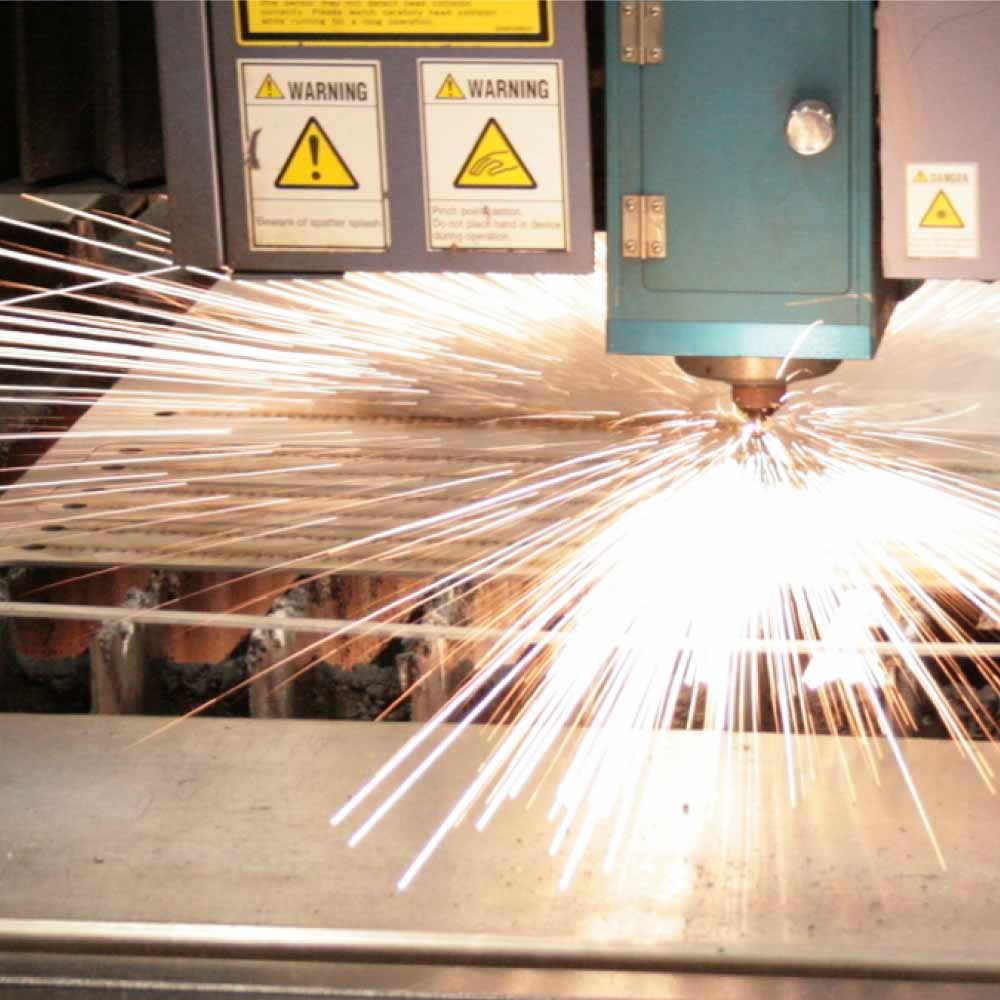

A team of highly skilled welders, fabricators, and inspectors deliver complex weldments, machining, assemblies, and finishes with ultra-precise tolerances, and have the certifications and rigorous quality data requirements to prove it.

-

NAVSEAcertified welders

-

AWScertified welders

-

DFARSmaterial compliant

-

ITARcompliant

-

ISO 9001-2015certified in-house inspectors

-

Raytheonapproved processes

-

NIST and CMMCcybersecurity compliant

-

DDTCregistered

What Others Are Saying

General Atomics is very pleased with Fox Metal Tech's ability to provide quality precision manufacturing services and the customer support needed to manufacture our custom enclosures for the EMALS program. Fox provided the manufacturing expertise that GA needed to ensure our requirements were met on the very first enclosure that was delivered. The results have saved GA time and resources in assembling and testing our equipment.

It’s been a pleasure working with you and your whole team. We couldn’t have done this without your whole team’s dedication and hard work! I look forward to working with Fox Valley on future projects as well.

Fox Valley Metal Tech has been a key partner/vendor of Campbell Wrapper Corporation and Circle Packaging Machinery, Inc. for the past 10 years for a variety of reasons, among them:

(1) Personal Attention: our sales contact, is very attentive to our unique needs…we’re not one of FVMT’s largest customers but we get treated like we are.

(2) Range of Capability: the investments FVMT has made in their equipment and people allow them to be a one-stop-shop for all fabricated components.

(3) Quality: their uncompromising attention to detail at all levels of their organization mean that we don’t need to inspect or worry about the quality of what they will provide.

FVMT is one of our key strategic supply partners. They consistently deliver top quality products, on-time at a competitive price. Our design engineering team has an intimate relationship with them where they bring tremendous value into our design process and they always find a way to say “yes”. And when there are issues, FVMT always does the “right thing”.

Fox Valley Metal Tech provides us with an excellent product, from the most complex of weldments to the simplest of assemblies. They have the ability to produce closely toleranced items with speed and accuracy, as well as provide certification of conformance to our specifications with their in house inspection capability. They have always been extremely helpful from the part development stage through production, keeping in contact with our engineers and procurement staff when problems or opportunities arise. FVMT’s knowledge of material behaviors and properties allows them to reduce waste and minimize development time for all types of products. Overall, an excellent supplier. They have helped us out of many tight spots during the manufacture of our military grade power production trailers.

Fox Valley Metal Tech has been a great partner for many years providing production parts and quick turn prototypes that support KI’s product development and custom furniture solutions. KI can rely on Fox to provide the quality required along with the quick deliveries needed to support our fast-paced business. Fox’s use of state of the art manufacturing equipment and value engineering provides a result that allows KI to be first to the market giving us the competitive edge over our competition.

Fox Valley Metal Tech has been an outstanding supplier and partner of Marinette Marine Corporation over the past ten years. During this period FVMT has demonstrated a high degree of flexibility in providing products to MMC’s most significant customers. For the US Navy’s Littoral Combat Ship (LCS) FVMT fabricated the mission hatch, mission space watertight doors, and the primary ship mast with outstanding quality and within demanding cost and schedule constraints. Additionally, FVMT fabricated a variety of components for the USCG’s Great Lakes Icebreaker, New York’s Staten Island Ferries, Navy Facilities Group Improved Navy Lighterage System (INLS) and the USCG’s Response Boat Medium (RBM). The products supplied for these projects required FVMT to extend beyond their core competencies integrating electrical, piping and insulation requirements. All these products were delivered on time and to the high quality standards expected of FVMT. As MMC expands its operation to meet the needs of the recently awarded LCS contract we expect FVMT to continue providing products to support our accelerated construction requirements.

When it comes to professionalism and expertise, FVMT is a trusted partner for our company. Not only can we count on a fair price from FVMT, but an exceptional product is always delivered. The personnel are always available for assistance in the design process which helps to set FVMT above the rest. In our industry quality and time are crucial, and FVMT is there with both to help our companies succeed.

It's What We Do

It's What We Do